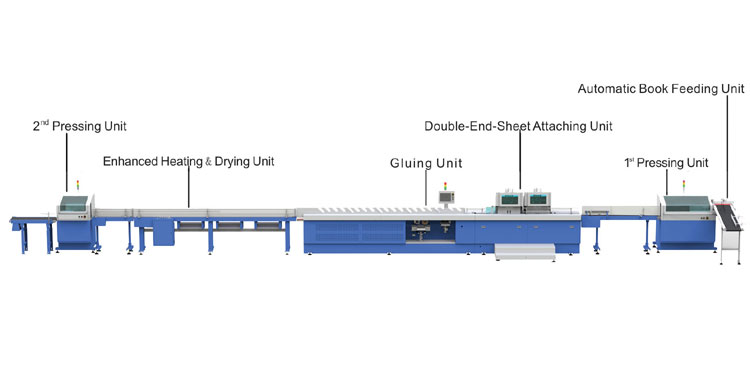

DH670B High-Speed Double-End-Sheet Spine Gluing and Binding System is used for the thread-sewn or pre-glued book blocks, and it can automatically finish all the process of pressing, end-sheet feeding, spine gluing, drying, and forming.

Outstanding Features

● The 1st pressing unit presses the book blocks and makes them firm, before entering into the end-sheet attaching unit and

the gluing unit, which ensures perfect gluing effect.

● Thanks to the gripper type feeding design, the end-sheets can be fed stably and reliably at high-speed. No adjustment

is needed.

● The latest design integrate the end-sheet attaching function, and the spine gluing function into one machine, which offers

easy operation and quick adjustment.

● It makes the front and rear end sheets firmly attaching with the book block, before entering into gluing unit, which can

avoid the problems of loose end sheets, and not even gluing effect.

● The book clamping unit employs 12B high tension chain, which ensures there is no vibration and wrong positioning during

the book transferring.

● The drying unit employs the gold-plated infrared lamp tube, which offers quick heating. The heating temperature

is adjustable.

● The 2nd pressing unit makes the book blocks firm after pressing, as well as ensures the end-sheet well attached with the

book block.

● It is capable to connect with three-knife trimmer for in-line production, which offers greater labor saving.

● Thanks to the 10 inch touch screen control, it makes the machine easy setup and user-friendly. Even low-skilled operator

can do the job well.