DH752 Sheet and CD Inserting Production Line is developed for automatically inserting sheets and CD. It is suitable for inserting the answer sheet, examination paper, saddle stitched book, perfect bound book, adhesive sticker and card into a book. It is also capable to insert thin book into another. It is an ideal automatic solution to greatly improve the efficiency of inserting production. The options of barcode laser system, label sticking system, barcode scanning system, and CD glue dotting system are available.

DH752 Sheet and CD Inserting Production Line consists of book feeding unit, automatic book separation unit, sheet separation unit, sheet feeding unit, CD clamping unit, automatic book stacking unit & other units. It can be equipped with two or more sheet feeding units, and supports the flexible integration with CD clamping unit.

The comprehensive quality control system, including missing signature detection, double signature detection, no book no signature feeding, and reject function, are equipped to ensure the product quality. The end-sheet inserting module can be offered as an option.

Outstanding Features

● Two or more signature feeding units capable to insert the examination paper and answer sheet at the

same time.

● Automatic book feeding system and automatic book collecting system to save the labor costs.

● High-speed book-clamping mechanism with stable performance. Automatic compensation for thin or

thick signature, and no adjustment needed.

● Modular design makes the production flexible, and different options of barcode laser system, label sticking system, barcode

scanning system and CD glue dotting system are available.

● Reliable performance and sturdy construction through employing the world-class brands of Schneider

and Panasonic electrical components.

● Stable performance and high production efficiency.

● Capable to connect with Three-Knife Trimmer for in-line production.

● Automatic Book Feeding Unit

- Capable to insert more than one book at a time, which can reduce the manpower, and can ensure the stability of high-speed production.

● Automatic High-Speed Book Separation Unit

- High-speed book separation through the air suction feeder design, and book pile height detection to control the automatic feeding of book.

● Automatic Signature Separation Unit

- Multi-direction adjustment, and stable signature separation. The end-sheet inserting module can be offered as option.

● Standard Two Sheet Feeding Stations

- Standard configuration with two sheet feeding stations. The 3rd and 4th feeding stations can be offered as option as per customer’s request.

- Automatic compensation for thin or thick signature, and no adjustment needed.

- Even the signature with thickness of 6mm capable to run well at high-speed production.

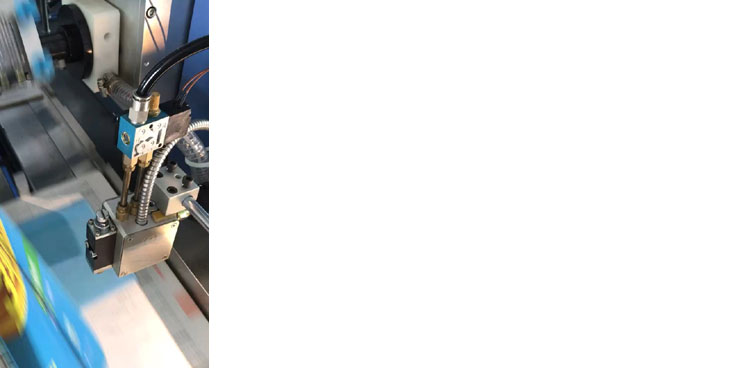

● Standard Two CD Inserting Stations

- Servo motor controlled clamping unit offers stable performance. Special designed pneumatic CD hopper can handle different kinds of CD, including the CD packed in the bag.

● Glue Dotting System (Option)

- The high-speed glue dotting system can be offered as an option, which can automatically dot the glue for sticking the CD on Page 2 (rear side of front cover sheet) or on Page 3 (the first page of book block).

● Label Sticking System (Option)

- The label sticking system can be offered as an option, which can automatically stick the label onto the product. This enables high-speed label sticking production in-line with the inserting production, which can greatly improve the production efficiency.

● High Speed Book Stacking Unit

- Stable production with high-speed up to 10000pcs/hour, and the book pile can be packed directly.